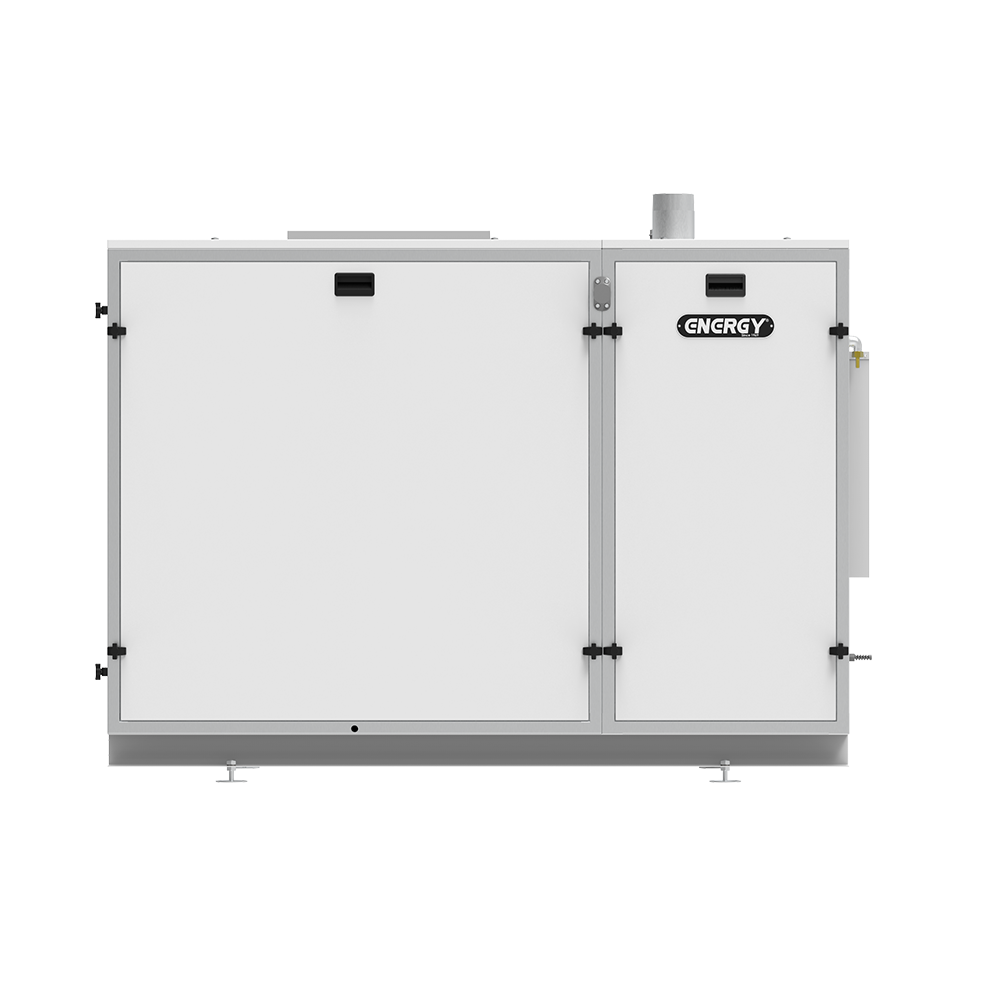

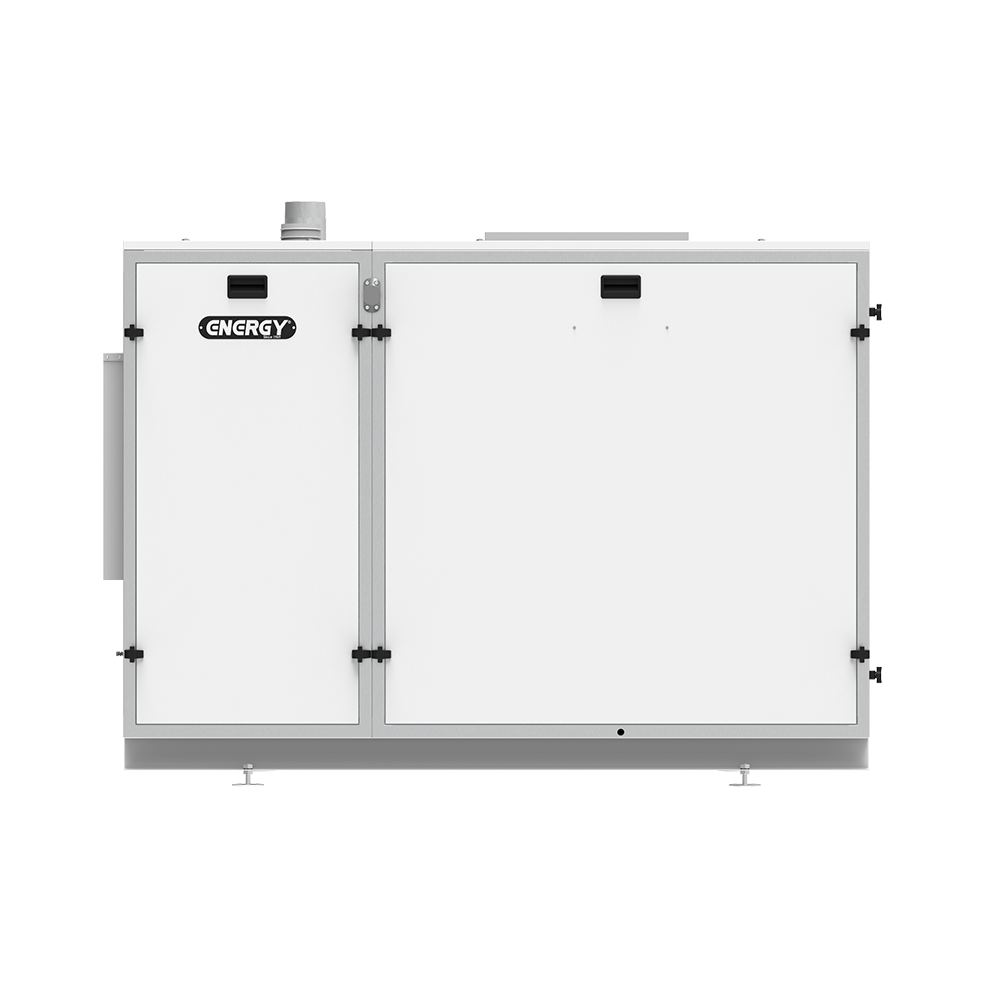

Description

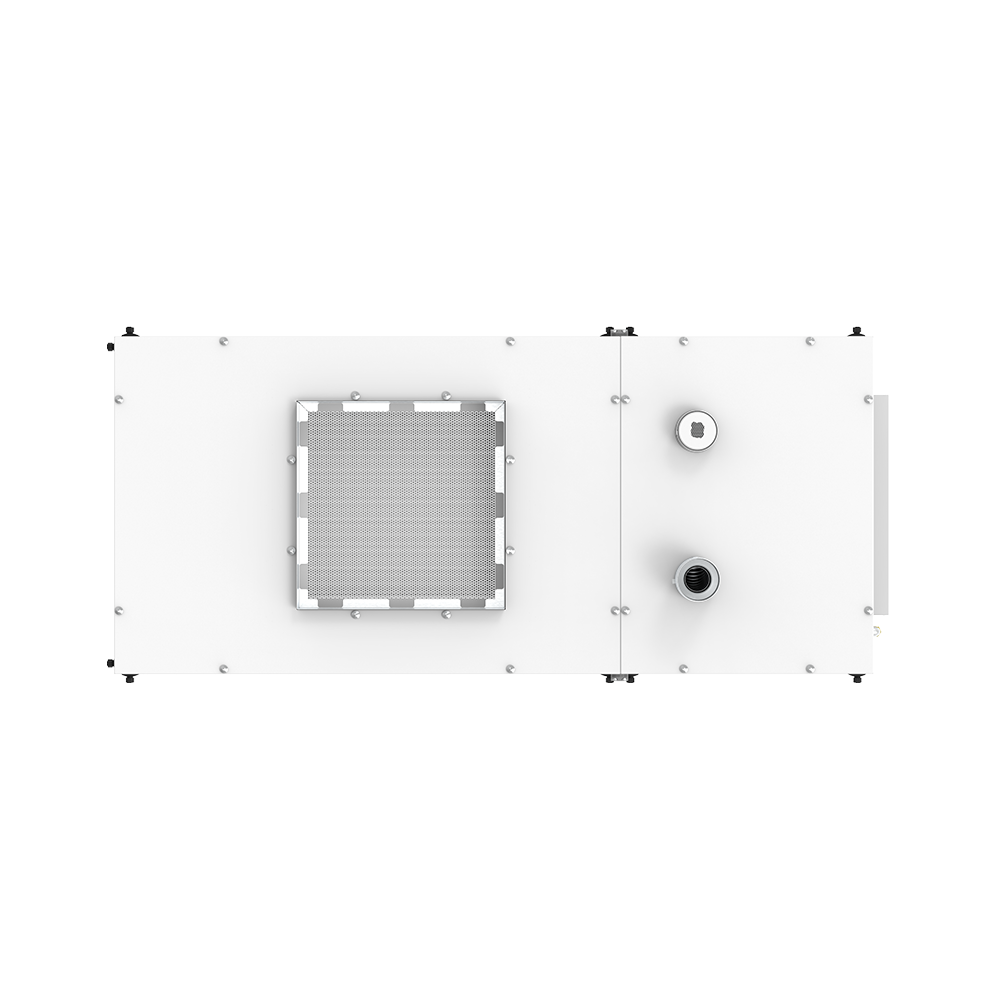

- More evaporative cooling efficiency by using a special cellulose pad

- Uniform distribution of water on the surface of the pad and the absence of a dry area

- Long life cellulose pad (3 to 5 years)

- High thermal efficiency and reduce fuel consumption by using the in-shot burner

- Natural gas heating with in-shot burner

- Fast heating and cooling with centrifugal fan (BLDC) and In-shot burner

- Low noise fan with BLDC motor

- Variable speed fan

- Low electrical power consumption in cooling and heating mode

- High Safety by thermostatic fan- limit control system

- Gas control valve

- Combustion air supply from outside (type C) or inside (type B)

- Durability and high corrosion resistance with aluminized steel heat exchanger

- Delay in fan operation before and after ignition

- Forced exhaust combustion products with fan

- Quick control of chimney operation

- High safety by fan Limit control thermostatic and gas control valve

- Automatic troubleshooting

- Flame monitoring

- Low fuel consumption with room temperature control

- Airflow with supply and return ducts (heating)-(max: 20m)

- User friendly (automatic ignition)

- Equipped with control panel cooling and heating mode.

- Equipped with Thermostatic control and timer

- Thermostatic control panel(heating/cooling)

- Timer and RF remote control

- Outdoor installation

Additional information

| Model | GM 0725 |

|---|---|

| Cooling System | Evaporative |

| Cooling Efficiency | 87% |

| cooling Area (Approx.) | 100-150 |

| Alr Flow | 3943-cfm |

| Fan Type | Centrifugal |

| Motor Power | (kW) hp |

| Electrical | A, V, ph |

| Heating System | Warm Air |

| Fuel Type | NG |

| Fuel Consumption | per hour |

| Heat Input | kcal/n (kW) |

| Thermal Efficiency (Gross- Net) | % |

| Heating Space (Appro.) | m^3 |